The Basics of Printing

In the printing industry, printers use all sorts of terms that, to the uninitiated, sound like a grab bag of random words and numbers strewn together. Words like “offset,” “spot,” “signature,” “plate,” “blanket,” and, of course, “hickey,” all seem like words chosen to confuse and confound. It’s completely understandable—literally none of those words use the generally accepted definition. With the overarching goal of keeping this topical and accessible, let’s dive right in with an overview of the printing process.

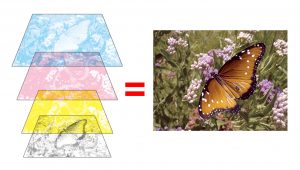

A single image split into four separations.

While we don’t use the original printing presses anymore (sorry, Gutenberg), the modern offset press works essentially the same, except instead of lining up thousands of individual letters by hand, it’s all done digitally. The PDF you send to us is fed into a RIP (raster image processor), which splits the PDF into four files: one cyan, one magenta, one yellow, and one black. This is because of the use of transparent inks meaning you can see through it like a piece of colored glass. These transparent layers of color are laid down, one on top of the other, to achieve almost every other color. A layer of yellow on top of a layer of cyan makes green, a layer of magenta on top of a layer of cyan makes purple, and so on. This is known as “process color,” or a “build,” because of the colors building up. Rarely, you might encounter “spot color,” or “spot.” This means a specific Pantone color and is mostly used when a company has a brand color that has to be exact, like Coca-Cola’s red (PMS 185c) or the yellow (PMS 123c) of McDonald’s.

Next, the four files are sent from the RIP to the platemaker. There are a few different styles, but what it does is laser etch the image onto a thin sheet of metal. There is a plate made for each color, which is one reason why full color is more expensive. In the case of spot color, another plate is made specifically for that one color. Each of these plates is then wrapped around a roller adjacent to another roller with a soft rubber-like layer (the blanket) wrapped around it. The plate is inked, passed to the blanket, and the paper is fed through. It comes out the other side with only that particular plate’s ink channel. Our presses are eight color perfecting, so the sheet is printed on one side by the first four units and flipped to print the back side of the sheet with the next four units. These presses help minimize the cost, but this process is the other reason why color is more expensive than black. Once the ink is dry, we move on to folding, collating, and binding.

Diagram of a traditional sixteen-page signature.

If you try to fold several sheets of paper at once, you will notice the edges don’t line up anymore. This is called “creep,” and it is due to the thickness of the paper. Each sheet of paper has to wrap around the one before it and, after several sheets, it becomes a serious problem. To combat this, printers developed “signatures.” A typical signature is a group of sixteen pages (eight sheets of paper, printed front and back, makes sixteen pages) that are folded and then stitched or stapled together. So, a ninety-six-page book would be divided into six signatures, each individually stitched, with all six signatures then bound together to make the book. This is why a signature has to be either all black or all color; even if there is only one color photo, the sheet still has to be fed through all four plates.

With this knowledge under your belt, you should be able to make sense of the terms that we use. The term “1/1,” or “one-color,” simply means only black ink will be used. The terms “4/4” (spoken as “four-over-four”), “build,” “process,” or “full-color” means cyan, magenta, yellow, and black inks will be used. “Spot,” or “spot color,” means a specific Pantone color, and it is always followed by a code, e.g., Spot PMS 147. “Collating” means putting the pages in order. “Signature” means consecutive pages that are stitched or stapled together. “Binding” means attaching those signatures together and gluing them into the cover. And, by the way, a “hickey” is just a bit of paper fiber and ink that hardens and collects on the plate, which causes a spot to appear on the paper where it shouldn’t be. Relax, Mom.

Jeremy Glanville

Graphic Designer

Donning Company Publishers

Jeremy Glanville presents the role of a graphic designer to his daughter's class at school.

This article was written by Donning designer Jeremy Glanville (left) and Donning editor Phil Briscoe (right).

Leave a Reply